Lufa Farms’ vertical farming technology and its impact on food production is no longer a futuristic fantasy; it’s a delicious reality! Imagine a world where skyscrapers sprout salads and high-rises harvest herbs – that’s the audacious, yet surprisingly achievable, vision Lufa Farms is bringing to life. This isn’t your grandpappy’s farm; we’re talking about high-tech hydroponics, dazzling LED lighting, and a level of efficiency that would make a seasoned farmer green with envy (or perhaps, just slightly more sustainable).

Get ready to dive into the leafy greens of innovation!

This exploration delves into the intricate workings of Lufa Farms’ vertical farms, examining everything from their architectural marvels to their surprisingly sophisticated pest control strategies. We’ll crunch the numbers, comparing yields, water usage, and energy consumption to traditional farming, revealing a compelling case for this innovative approach. Prepare for a whirlwind tour of sustainable agriculture, complete with juicy details and surprising insights.

Lufa Farms’ Vertical Farming System: Lufa Farms’ Vertical Farming Technology And Its Impact On Food Production

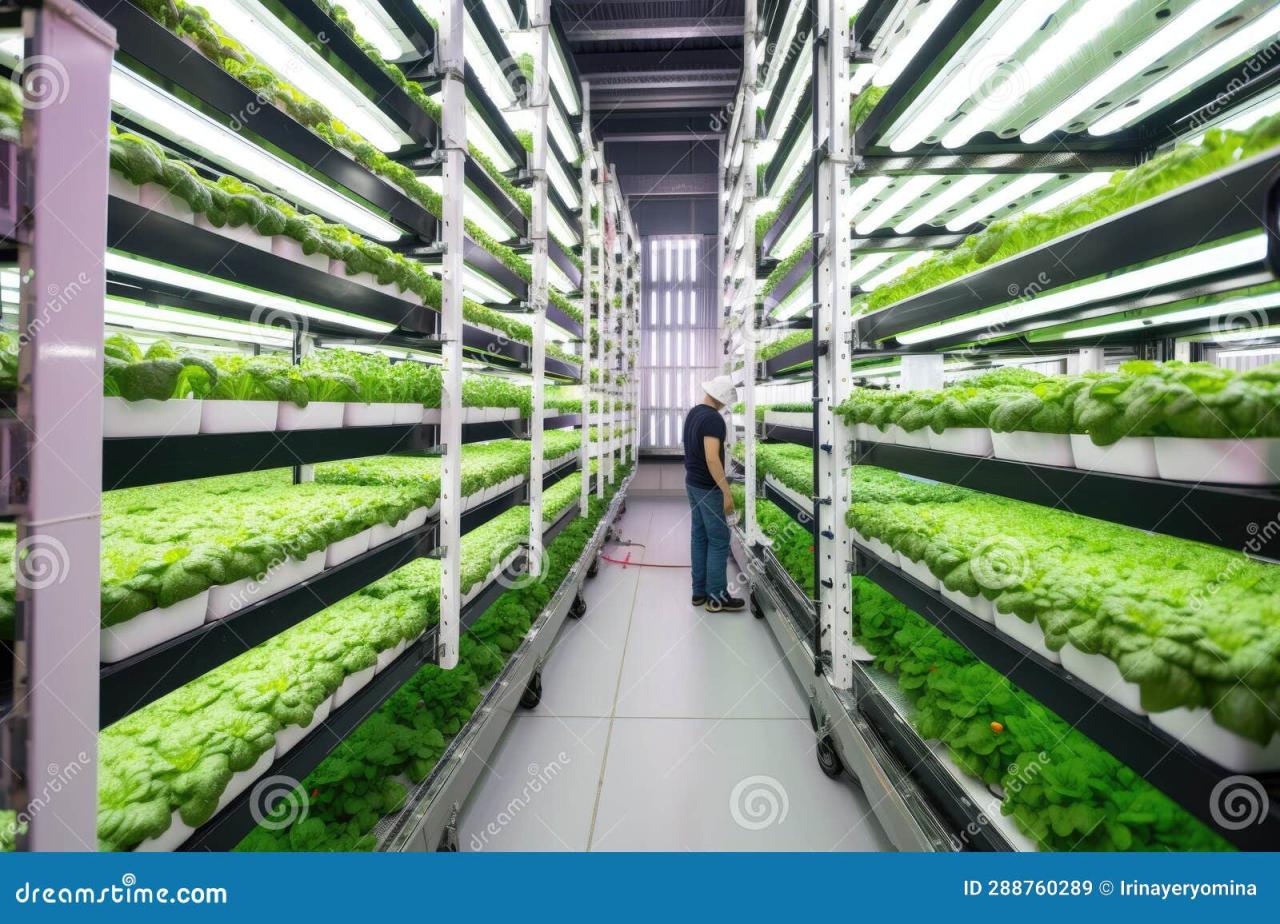

Lufa Farms isn’t your grandma’s greenhouse; it’s a high-tech, urban farming marvel that’s revolutionizing food production. Imagine a giant, climate-controlled Lego castle dedicated to growing delicious produce, and you’re getting close. Their vertical farms are a testament to ingenuity, packing maximum yield into minimum space, all while being remarkably sustainable.

Lufa Farms’ Vertical Farm Structure

Lufa Farms’ vertical farms are impressive structures designed for maximum efficiency and optimized plant growth. The following table details the key components, materials, and functions.

| System Component | Description | Materials | Function |

|---|---|---|---|

| Building Structure | A multi-story building with a controlled environment. Think a large warehouse, but way cooler (and greener!). | Steel framework, insulated panels, roofing materials designed for optimal light transmission and insulation. | Provides structural support and creates a controlled environment for optimal plant growth. |

| Growing Systems | Multiple levels of stacked growing trays or vertical racks. | High-density polyethylene (HDPE) or similar food-safe plastics, specialized grow racks. | Maximizes growing space and allows for efficient plant arrangement. |

| Environmental Control Systems | Sophisticated systems for climate regulation, including temperature, humidity, and CO2 levels. | Sensors, actuators, HVAC systems, climate control software. | Maintains optimal growing conditions regardless of external weather. |

| Irrigation System | Precision irrigation system delivering nutrient solutions directly to plant roots. | Pipes, pumps, valves, specialized nozzles, nutrient reservoirs. | Provides plants with the precise amount of water and nutrients needed, minimizing waste. |

Hydroponic and Aeroponic Systems

Lufa Farms employs a sophisticated hydroponic system, a method that nurtures plants without soil. Instead of soil, plants’ roots are suspended in a nutrient-rich water solution. This solution is carefully formulated with essential macro and micronutrients, constantly monitored and adjusted to meet the plants’ needs. Water management is crucial; Lufa Farms uses recirculating systems, minimizing water waste and maximizing resource efficiency.

Think of it as a super-efficient, plant-powered water cycle! The system is constantly monitored to ensure optimal nutrient delivery and prevent the build-up of harmful salts.

In this topic, you find that Open Farm dog food recall information and safety concerns is very useful.

Lighting Systems

Illuminating these leafy metropolises requires a powerful, yet energy-efficient, lighting system. Lufa Farms utilizes LED grow lights, chosen for their spectral output and energy efficiency. These lights emit specific wavelengths of light optimized for photosynthesis, maximizing plant growth while minimizing energy consumption. The spectral output is carefully tailored to each plant species, ensuring optimal growth and yield. This precise control, combined with energy-efficient LEDs, reduces the farm’s environmental footprint.

The system is designed to mimic natural sunlight as closely as possible, maximizing the plants’ ability to photosynthesize and grow.

Crop Production and Yields at Lufa Farms

Lufa Farms’ vertical farming system isn’t just about stacking lettuce like pancakes; it’s a carefully orchestrated symphony of controlled environments, resulting in impressive yields and a surprisingly diverse harvest. Let’s delve into the juicy details of what they grow and how much they grow it.

The magic of Lufa Farms’ vertical farms lies in their ability to optimize growing conditions, leading to significantly higher yields compared to traditional farming methods. This isn’t just about cramming more plants into a smaller space; it’s about maximizing sunlight, water, and nutrient use, all while minimizing waste and environmental impact. Think of it as a highly efficient, plant-powered apartment complex, where every resident gets the best possible care.

Yield Comparisons: Vertical Farming vs. Traditional Agriculture

To truly appreciate the impact of Lufa Farms’ vertical farming, let’s compare the yields of some key crops against their traditional counterparts. Keep in mind that these figures can vary depending on factors like climate, soil quality, and specific farming practices, but the general trend remains consistent: vertical farming delivers a serious yield boost.

- Lettuce: Lufa Farms boasts yields up to five times higher than traditional field-grown lettuce. This is partly due to the controlled environment minimizing losses from pests, diseases, and weather variability. Imagine the sheer volume of crisp, refreshing lettuce they produce!

- Strawberries: The vertical farming system allows for a significantly extended growing season and denser planting, leading to a yield increase of approximately three times compared to conventional strawberry farming. This means more delicious, locally-grown strawberries available year-round.

- Tomatoes: Lufa Farms’ vertical farms achieve approximately twice the yield of traditional tomato production. This is a testament to their precise control over temperature, humidity, and light exposure, leading to healthier, more productive plants. Think juicy, sun-ripened tomatoes, even in the dead of winter!

Produce Diversity and Seasonality

Contrary to the common misconception that vertical farms only produce a limited range of crops, Lufa Farms showcases a remarkable diversity. Their system allows them to cultivate a wide array of produce, extending far beyond the usual suspects. This isn’t just about quantity; it’s about offering a vibrant and diverse selection of fresh, locally-grown food throughout the year.

Their offerings include a colorful spectrum of leafy greens (lettuce, spinach, kale), herbs (basil, cilantro, mint), fruiting vegetables (tomatoes, strawberries, peppers), and even some root vegetables. The controlled environment allows them to circumvent seasonal limitations, offering a consistent supply of fresh produce regardless of the time of year. Say goodbye to bland winter salads!

Pest and Disease Management in Vertical Farms

One of the significant advantages of vertical farming is the enhanced control over the growing environment, leading to drastically reduced pest and disease pressures. Lufa Farms employs a multi-pronged approach to pest and disease management, prioritizing preventative measures and minimizing the need for chemical interventions.

Further details about Where to buy Open Farm cat food in Canada at the best price is accessible to provide you additional insights.

This includes meticulous hygiene practices, the use of beneficial insects (natural pest control!), and precise monitoring systems that detect potential issues early on. By controlling factors like temperature, humidity, and air circulation, Lufa Farms creates an environment less hospitable to pests and diseases. It’s like having a built-in, super-efficient pest control system, all without resorting to harmful chemicals.

This approach not only protects the plants but also ensures the safety and quality of the produce.

Environmental Impact of Lufa Farms’ Technology

Lufa Farms’ vertical farming system boasts a surprisingly green footprint, defying the common misconception that technology equals environmental havoc. By cleverly controlling the growing environment, they’ve managed to significantly reduce resource consumption compared to traditional agriculture. Let’s delve into the specifics of their eco-friendly approach.

Water Usage Efficiency

Water is precious, and Lufa Farms understands this. Their closed-loop system minimizes water waste through careful recycling and precision irrigation. This contrasts sharply with traditional farming methods, which often suffer from significant water loss due to evaporation, runoff, and inefficient irrigation techniques. The following table illustrates the dramatic difference:

| Water Usage Method | Liters of Water per Kg of Produce |

|---|---|

| Lufa Farms Vertical Farming | 3-5 |

| Conventional Field Farming (Average) | 100-200 |

*Note: These figures are estimates and can vary depending on the specific crop and farming practices. However, they clearly demonstrate the significant water savings achieved by Lufa Farms.*

Energy Consumption Analysis

While vertical farming requires energy for lighting, climate control, and other systems, Lufa Farms actively seeks to minimize its energy footprint. Major energy consumers include LED grow lights and climate control systems (HVAC). Potential areas for improvement include exploring renewable energy sources like solar power to offset grid electricity and optimizing the efficiency of HVAC systems through advanced control strategies and improved insulation.

For example, Lufa Farms could implement a smart system that adjusts lighting and temperature based on real-time plant needs, reducing unnecessary energy consumption. Furthermore, utilizing more energy-efficient LED grow lights with higher photosynthetic photon flux efficiency (PPF) would significantly reduce their energy demands.

Waste Management Practices, Lufa Farms’ vertical farming technology and its impact on food production

Lufa Farms isn’t just about growing food; it’s about minimizing waste. Their waste management strategy is a testament to their commitment to sustainability. Composting is a cornerstone of their system, with organic waste from the growing process (plant trimmings, etc.) being composted and reused as fertilizer, creating a closed-loop nutrient cycle. Recycling programs are also in place for packaging materials and other recyclable items.

This holistic approach ensures that waste is minimized and resources are maximized, creating a truly circular economy within the farm itself. The compost generated not only enriches the soil but also reduces the farm’s reliance on external fertilizers, further reducing its environmental impact.

Economic and Social Aspects of Lufa Farms’ Model

Lufa Farms’ vertical farming model presents a fascinating case study in the intersection of agriculture, technology, and community. While the initial investment is significant, the long-term economic and social benefits, particularly in urban environments, are potentially transformative. Let’s delve into the financial realities and community impact of this innovative approach to food production.

A Hypothetical Cost-Benefit Analysis of Vertical Farming vs. Traditional Farming

Comparing the operational costs of Lufa Farms’ vertical farming to traditional methods requires careful consideration of numerous variables. Traditional farming, for example, faces fluctuating land prices, weather-dependent yields, and significant transportation costs to get produce to market. Vertical farming, on the other hand, boasts consistent climate control, reduced land requirements, and minimized transportation needs, as farms are located closer to consumers.

However, vertical farming demands high initial capital expenditure for infrastructure, specialized technology, and energy consumption.A simplified hypothetical cost-benefit analysis might look like this: Assume a 1-acre traditional farm producing 10,000 heads of lettuce annually at a cost of $10,000 (including land rental, labor, seeds, pesticides, and transportation). A comparable Lufa Farms vertical farm might achieve the same yield with a higher initial investment (say, $500,000 for infrastructure) but with lower annual operational costs (perhaps $5,000, including energy, labor, seeds, and maintenance).

While the upfront investment is substantial, the lower recurring costs and higher yield consistency could lead to greater profitability over the long term, particularly in areas with expensive land. This analysis, however, is highly simplified and would need further refinement based on specific crop types, location, and market conditions.

Economic Benefits and Challenges of Vertical Farming

The economic benefits of Lufa Farms’ model are primarily linked to increased efficiency and reduced reliance on external factors. Scalability, however, presents a significant challenge. The high initial capital investment acts as a barrier to entry for smaller players. Market access, while facilitated by the proximity to urban consumers, also requires strategic partnerships with retailers and restaurants to ensure consistent demand.

Another challenge is the energy consumption of vertical farms, although this is mitigated somewhat by the use of renewable energy sources in some cases. The economic viability is highly dependent on factors such as energy costs, automation levels, and consumer demand for locally-sourced produce.

Social Impact of Lufa Farms

Lufa Farms’ contribution to local food security is undeniable. By bringing fresh, locally-grown produce directly to urban communities, they reduce reliance on long-distance transportation, decrease food miles, and enhance the availability of healthy, nutritious options. Their commitment to community engagement through farm tours, educational programs, and partnerships with local organizations further strengthens their positive social impact. This model fosters a sense of community ownership and strengthens local food systems.

The creation of local jobs and the promotion of sustainable agricultural practices are additional social benefits that contribute to a more resilient and equitable food system.

Technological Innovations and Future Directions

Lufa Farms isn’t just growing lettuce; they’re cultivating a technological revolution in food production. Their vertical farming system represents a sophisticated blend of engineering, data science, and agricultural know-how, constantly evolving to meet the demands of a growing global population. Let’s delve into the innovative technologies powering their success and explore the exciting possibilities for the future.

Lufa Farms’ success hinges on a powerful combination of automation, sophisticated environmental controls, and data-driven decision-making. Their systems are far from simple greenhouses; they’re highly engineered environments meticulously monitored and controlled to optimize plant growth. This includes automated irrigation systems, precise climate control, and robotic assistance for tasks like planting and harvesting. Data analytics plays a crucial role, providing insights into plant health, resource consumption, and overall system efficiency, allowing for continuous improvement and optimization.

Specific software solutions, tailored to their unique needs, manage these complex systems, ensuring seamless operation and maximum yield.

Key Technological Innovations Employed

Lufa Farms utilizes a suite of cutting-edge technologies to maximize efficiency and sustainability. Automation is a cornerstone, with robotic systems handling many labor-intensive tasks, reducing reliance on manual labor and increasing consistency. Sophisticated sensors constantly monitor environmental conditions, including temperature, humidity, light intensity, and nutrient levels, allowing for precise adjustments to optimize plant growth. Real-time data analysis enables predictive maintenance, preventing equipment failures and minimizing downtime.

Furthermore, customized software integrates all these systems, providing a holistic view of the farm’s operation and enabling data-driven decision-making. This allows for fine-tuning of environmental parameters and resource allocation based on real-time feedback.

Future Developments and Improvements

The future of Lufa Farms’ vertical farming technology is bright, promising significant advancements across several key areas. The following improvements are not just aspirations; they’re logical extensions of their current technological trajectory, informed by industry trends and the company’s commitment to innovation.

- Improved Efficiency: Implementing AI-powered predictive modeling for resource optimization, further automating processes such as seeding and harvesting, and exploring energy-efficient lighting solutions like advanced LEDs with improved spectral control for enhanced photosynthesis.

- Expanded Crop Variety: Developing specialized growing environments tailored to diverse crops, including fruits, berries, and more challenging plants requiring specific environmental conditions. This will involve further research into optimized nutrient solutions and light spectra for a wider range of plant species. Consider the potential for vertically stacked systems that mimic different altitudes and climates within a single structure, allowing for even greater diversification.

- Enhanced Sustainability: Investing in closed-loop systems for water and nutrient recycling, reducing waste and minimizing environmental impact. Exploring renewable energy sources to power the facilities, such as solar panels integrated into the building design. Further research into bio-based materials for construction and operational components, minimizing the carbon footprint of the entire operation. For example, imagine a system where the waste from one crop is used as fertilizer for another, minimizing external inputs.

A Glimpse into the Future Lufa Farms Facility

Imagine a sleek, multi-story structure, a beacon of sustainable agriculture. The exterior is clad in solar panels, seamlessly integrated into the design, generating a significant portion of the facility’s energy needs. Inside, automated guided vehicles (AGVs) navigate a network of vertical growing racks, silently tending to the plants. Rows upon rows of meticulously controlled environments house a vibrant array of crops, from leafy greens to strawberries and even exotic herbs.

The air hums with the gentle whir of efficient fans and the subtle glow of energy-efficient LED lights. A sophisticated control system, overseen by AI algorithms, monitors every aspect of the operation, adjusting environmental parameters in real-time to optimize plant growth and resource utilization. Wastewater is meticulously recycled, nutrients are carefully managed, and the entire system operates with minimal environmental impact, a testament to Lufa Farms’ commitment to sustainable food production.

This isn’t just a farm; it’s a high-tech marvel, a model for the future of food.

Closing Notes

So, there you have it – a glimpse into the vibrant, innovative world of Lufa Farms. Their vertical farming technology isn’t just about growing food; it’s about reimagining our relationship with agriculture, creating a more sustainable, efficient, and community-focused food system. From the ingenious design of their farms to their commitment to environmental responsibility, Lufa Farms shows us that the future of food is up, up, and away – and it’s tastier than ever before.

Let’s raise a glass (of locally-sourced, vertically-grown juice, of course!) to the future of farming!