Lufa Farms vertical farming technology and benefits: Imagine a world where skyscrapers sprout salad, not steel. That’s the delicious reality Lufa Farms is crafting, defying gravity and growing greens in urban jungles. Forget dusty fields; these urban farmers are pioneering a revolution in food production, using ingenious technology to cultivate crops vertically, maximizing space and minimizing environmental impact.

Get ready to explore a world where lettuce leaps tall buildings in a single bound (well, maybe not that high, but you get the idea!).

This innovative approach tackles issues of food miles, pesticide use, and water conservation with impressive efficiency. From the ingenious climate control systems to the precise sensors monitoring every sprout, Lufa Farms’ vertical farms are a testament to human ingenuity and a sustainable future for food. We’ll delve into the technical wizardry, environmental wins, economic advantages, and social impact of this remarkable undertaking, uncovering the secrets behind their leafy success.

Lufa Farms’ Vertical Farming System

Lufa Farms isn’t just growing lettuce; they’re growing the future of food production, one vertically stacked layer at a time. Their system represents a sophisticated blend of engineering, horticulture, and a healthy dose of tech-savvy ingenuity. Let’s delve into the nuts and bolts (and LEDs!) of their impressive operation.

Their vertical farms are essentially highly controlled indoor environments designed to maximize plant growth while minimizing resource consumption. Think of them as giant, climate-controlled greenhouses, but way more efficient and high-tech.

Growing Structures and Climate Control

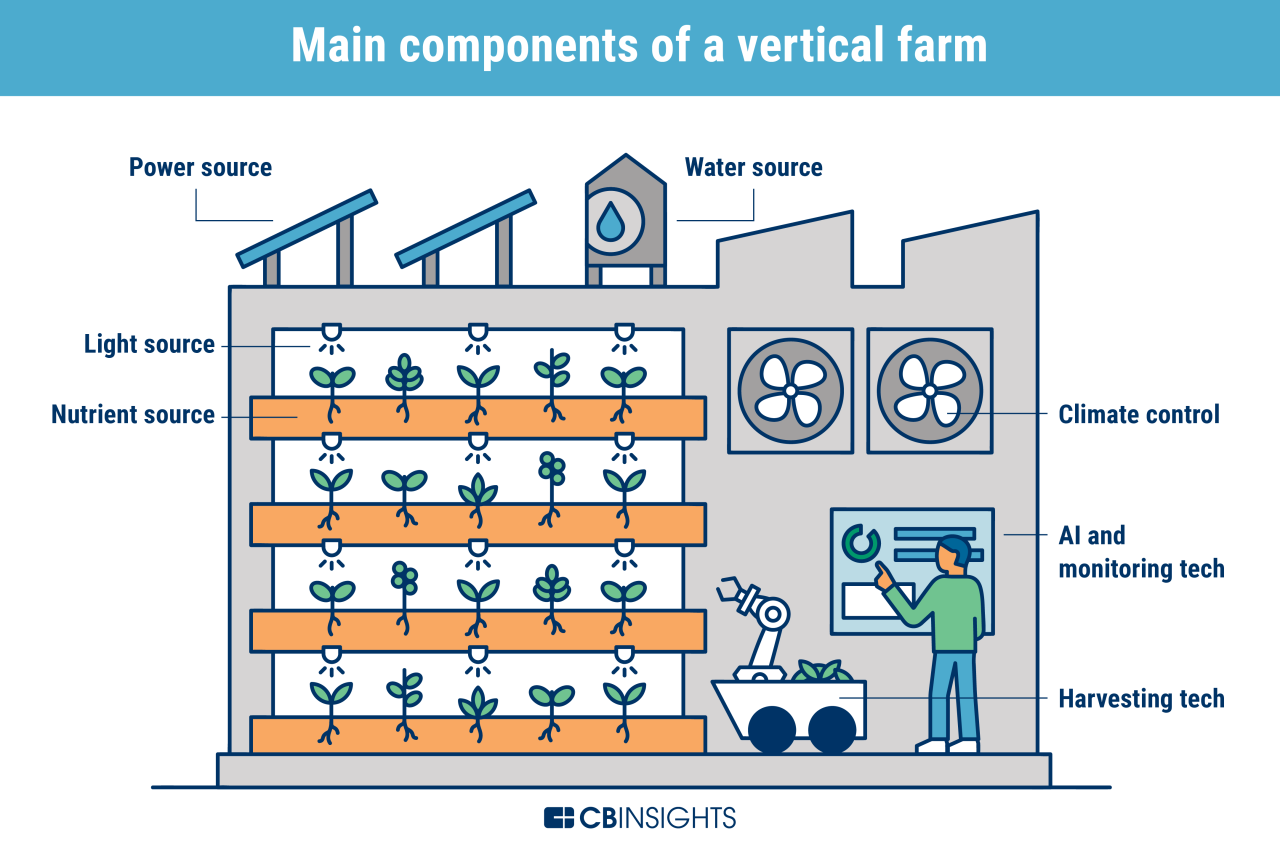

Lufa Farms utilizes multi-tiered structures, often within repurposed industrial spaces. These structures maximize vertical space, allowing for a significant increase in crop yield per square foot compared to traditional farming. Climate control is meticulously managed, using sophisticated systems to regulate temperature, humidity, and air circulation. This ensures optimal growing conditions for a variety of crops, regardless of external weather conditions.

Imagine a perfectly tailored climate for each plant, from the moment its seed sprouts to the day it’s harvested – a horticultural paradise!

Irrigation Methods

Instead of relying on unpredictable rainfall, Lufa Farms employs precision irrigation techniques. Drip irrigation systems deliver water directly to the plant roots, minimizing water waste and ensuring consistent moisture levels. This targeted approach reduces water consumption significantly compared to traditional flood irrigation methods, making the system incredibly water-efficient. It’s like giving each plant a personalized spa treatment, all while saving precious water resources.

Energy Efficiency Measures

Lufa Farms is committed to sustainable practices, and energy efficiency is a top priority. They utilize LED grow lights, known for their high energy efficiency and ability to provide the specific wavelengths of light that plants need for optimal growth. They also implement smart energy management systems to monitor and optimize energy consumption throughout the facility. This reduces their carbon footprint and keeps operational costs in check – a win-win situation for both the environment and their bottom line.

Sensors and Monitoring Systems

Think of Lufa Farms’ vertical farms as high-tech, plant-monitoring observatories. A network of sensors continuously monitors environmental parameters like temperature, humidity, light intensity, and nutrient levels in the irrigation water. This data is fed into sophisticated software systems that provide real-time insights into plant health and growth. Any deviations from optimal conditions trigger alerts, allowing the team to make adjustments and prevent problems before they escalate.

It’s like having a dedicated team of plant doctors constantly monitoring the health of every single plant.

Comparison of Lufa Farms and Traditional Agriculture

Here’s a table highlighting the key differences between Lufa Farms’ vertical farming and traditional agriculture methods:

| Feature | Lufa Farms | Traditional Agriculture | Key Differences |

|---|---|---|---|

| Land Use | Highly efficient vertical stacking | Large land areas required | Significantly reduced land footprint |

| Water Usage | Precision irrigation, minimal waste | Flood irrigation, high water consumption | Substantially lower water consumption |

| Energy Consumption | LED lighting, energy-efficient systems | Sun-dependent, less control over energy use | Potentially higher energy use for lighting, but offset by other efficiencies |

| Yield | High yield per square foot | Yield varies depending on weather and other factors | Higher and more consistent yields |

| Environmental Impact | Reduced water and land use, controlled environment reduces pesticide needs | Higher water and land use, potential for pesticide runoff and soil degradation | Lower environmental impact overall |

Environmental Impact of Lufa Farms’ Approach

Lufa Farms’ vertical farming isn’t just about growing delicious produce; it’s about growing a greener future. By cleverly stacking crops and optimizing resources, they’ve managed to significantly reduce their environmental footprint compared to traditional farming methods. Let’s delve into the specifics of how they’re making a difference, one leafy green at a time.

Water Consumption Reduction

Traditional agriculture is notoriously thirsty. Vast quantities of water are needed for irrigation, often leading to depletion of groundwater resources and environmental stress. Lufa Farms, however, utilizes a closed-loop hydroponic system. This means that water is recirculated and reused, minimizing waste and dramatically reducing water consumption. Instead of letting precious water soak into the ground and potentially run off, Lufa Farms meticulously monitors and recycles it, resulting in a water usage significantly lower than conventional farming practices.

Estimates suggest a reduction of up to 95% compared to field-grown crops, depending on the specific crop and climate. Imagine the impact if every farm adopted such efficient water management!

Minimized Pesticide and Herbicide Use

The absence of soil in Lufa Farms’ vertical farms creates a less hospitable environment for pests and weeds. This significantly reduces the need for pesticides and herbicides, leading to cleaner produce and a healthier environment. The controlled environment allows for precise monitoring and targeted interventions, further minimizing the reliance on harmful chemicals. This translates to less pesticide runoff contaminating water sources and less exposure for farmworkers and consumers.

The result is a safer, healthier food system for everyone involved.

Carbon Footprint Comparison

Transporting produce from distant farms contributes significantly to greenhouse gas emissions. Lufa Farms’ urban farms are strategically located close to consumers, drastically reducing transportation distances and associated carbon emissions. Furthermore, the controlled environment of vertical farming allows for optimized energy use, reducing the overall energy consumption and carbon footprint compared to traditional farming, which often relies on heavy machinery and extensive land clearing.

While the initial construction of a vertical farm has an environmental cost, the long-term operational benefits in terms of reduced transportation and energy use outweigh these initial impacts. Studies comparing similar-sized operations suggest a significantly lower carbon footprint for Lufa Farms.

Waste Management Practices

Lufa Farms takes a comprehensive approach to waste management. Compostable materials from the growing process are recycled and reused as fertilizer, creating a closed-loop system that minimizes waste and reduces reliance on external inputs. Excess water, as mentioned earlier, is also meticulously recycled. By carefully managing and repurposing waste streams, Lufa Farms demonstrates a commitment to sustainability that goes beyond simply growing food; it’s about minimizing the overall impact on the planet.

This conscientious waste management is a key component of their overall environmentally responsible operation.

Economic Aspects of Lufa Farms’ Model

Lufa Farms’ vertical farming model presents a compelling economic case, challenging traditional agricultural norms and offering a glimpse into the future of food production. While initial investment is significant, the long-term economic benefits, driven by increased efficiency and reduced reliance on external factors, paint a picture of sustainable profitability. Let’s delve into the specifics of Lufa Farms’ financial success and explore how a similar model could be replicated.

The cost-effectiveness of Lufa Farms’ vertical farming system compared to traditional agriculture is a significant factor in its success. Traditional farming relies heavily on vast tracts of land, often located far from urban centers, incurring high transportation costs. Labor costs are also substantial, involving seasonal workers and demanding physical labor. Lufa Farms, by contrast, utilizes a much smaller footprint, reducing land acquisition and maintenance expenses drastically.

Furthermore, its controlled environment minimizes the need for extensive manual labor, relying instead on automated systems and a smaller, highly skilled workforce. Energy consumption is a key consideration; Lufa Farms employs energy-efficient LED lighting and optimized climate control systems to minimize its environmental footprint and operational expenses, though this remains a significant operational cost.

Pricing Strategies for Profitability and Accessibility

Lufa Farms employs a direct-to-consumer model, primarily through its online platform and local delivery services. This eliminates intermediary costs, allowing for competitive pricing while maintaining profitability. Their pricing strategy balances the premium associated with high-quality, locally sourced produce with the need for accessibility. They offer a range of products at varying price points to cater to diverse consumer needs and budgets, achieving a balance between premium pricing for specialty items and competitive pricing for staple produce.

This targeted approach allows them to reach a broader customer base while maintaining a healthy profit margin.

Economic Benefits Experienced by Lufa Farms

Lufa Farms has reported significantly increased yields compared to traditional farming methods. The controlled environment allows for year-round production, maximizing output and minimizing losses due to weather or pests. This high yield directly translates into increased revenue. Simultaneously, the reduction in land use, labor costs, and transportation expenses contributes to significantly lower operational costs. The combination of increased revenue and reduced expenses creates a robust financial foundation for the company’s continued growth and expansion.

For example, their ability to produce a consistent supply of high-quality lettuce throughout the year, regardless of external weather conditions, has proven a major economic advantage.

Hypothetical Business Model for a Similar Vertical Farm

Let’s imagine a new vertical farm, “CityGreens,” located in a densely populated urban area. The initial investment would include the cost of building a state-of-the-art vertical farm facility (estimated at $5 million), purchasing specialized equipment (LED lighting, hydroponic systems, climate control), and establishing a robust online ordering and delivery system (approximately $1 million). Operating costs would encompass energy consumption, water usage, labor (skilled technicians and delivery personnel), seeds, nutrients, and maintenance.

We estimate annual operating costs to be around $1.5 million. Revenue streams would include direct sales to consumers via an online platform and partnerships with local restaurants and grocery stores. Assuming an average annual revenue of $3 million, CityGreens could achieve profitability within three years, with potential for significant growth as demand for locally sourced produce increases.

This model highlights the economic viability of vertical farming in urban environments, emphasizing the potential for substantial returns on investment with effective management and strategic planning.

Social and Community Impact: Lufa Farms Vertical Farming Technology And Benefits

Lufa Farms isn’t just growing food; it’s cultivating community. Their vertical farming model isn’t just about efficient agriculture; it’s about building stronger, more resilient neighborhoods. By integrating directly with local communities, Lufa Farms demonstrates that sustainable food production can be a powerful force for positive social change. This goes beyond simply providing fresh produce; it’s about fostering a sense of shared responsibility and building a better future, one delicious, locally-grown tomato at a time.Lufa Farms’ community engagement isn’t a side project; it’s woven into the fabric of their operations.

They actively seek to engage with local residents, fostering a sense of ownership and participation in the process of growing food. This isn’t your grandpa’s farm; it’s a high-tech, community-focused operation that’s changing the way we think about food production and its social impact.

Community Engagement Strategies

Lufa Farms employs a multi-pronged approach to community engagement. They host farm tours, educational workshops, and community events at their facilities, allowing residents to see firsthand the technology and processes involved in vertical farming. They also partner with local schools and organizations to offer educational programs and volunteer opportunities, creating a ripple effect of engagement that extends beyond their immediate customer base.

Furthermore, Lufa Farms actively collaborates with local businesses and community leaders to foster a sense of shared responsibility and mutual support within the neighborhood. These partnerships extend the reach of their social impact, creating a truly collaborative approach to community building.

Impact on Local Food Security and Accessibility

By establishing vertical farms within urban centers, Lufa Farms significantly improves local food security and accessibility. Their model reduces reliance on long-distance transportation, decreasing the carbon footprint while simultaneously ensuring a consistent supply of fresh, high-quality produce. This is especially beneficial for communities with limited access to fresh food, often referred to as “food deserts.” Imagine a neighborhood previously lacking readily available healthy options now boasting a vibrant, local source of nutritious produce – that’s the impact Lufa Farms is making.

Their commitment to affordability also makes their produce accessible to a wider range of consumers, contributing to healthier and more equitable communities. For example, their community-supported agriculture (CSA) programs offer affordable access to fresh produce for families who might otherwise struggle to afford it.

Job Creation

Lufa Farms’ operations generate a significant number of jobs within the local community. These aren’t just your average farm jobs; they encompass a wide range of skills, from agricultural technicians and engineers to marketing and sales professionals. This creates a diverse and skilled workforce, contributing to the economic vitality of the surrounding area. Furthermore, the company’s commitment to fair wages and employee benefits contributes to a more stable and prosperous community.

The creation of these jobs is not limited to highly skilled roles; it also includes opportunities for entry-level positions, providing pathways for individuals seeking employment and professional development. This inclusive approach further strengthens the social fabric of the community.

Social Benefits of Lufa Farms’ Vertical Farming Model

The social benefits of Lufa Farms’ model extend far beyond simply providing jobs and fresh food. Let’s summarize the positive impacts:

- Increased access to fresh, healthy food in underserved communities.

- Creation of diverse and well-paying job opportunities.

- Enhanced community engagement and social cohesion through educational programs and events.

- Reduced environmental impact through localized food production.

- Promotion of sustainable agricultural practices and food systems.

- Empowerment of local communities through increased food security and self-sufficiency.

Challenges and Future Directions for Lufa Farms

Lufa Farms, while a pioneering force in vertical farming, faces a unique set of hurdles as it strives to scale its operations and solidify its position in the future of food production. Balancing innovation with profitability, while navigating the complexities of a rapidly evolving technological landscape, presents a fascinating challenge for this urban farming giant. Let’s delve into the key areas that will shape Lufa Farms’ trajectory.

Scaling Challenges

Scaling up vertical farming presents significant logistical and economic challenges. The initial investment in infrastructure is substantial, requiring significant capital for building and equipping large-scale vertical farms. Furthermore, maintaining consistent high yields across a larger operation demands advanced automation and precise environmental control, which can be complex and expensive to implement and maintain. For example, a sudden power outage in a large facility could result in significant crop loss, highlighting the vulnerability of this technology to external factors.

Finding and training skilled personnel to manage and maintain these complex systems is another crucial aspect of scaling. Lufa Farms needs to strategically manage its growth to avoid overextending its resources and compromising quality.

Technological Advancements for Improved Efficiency and Sustainability

Several technological advancements could significantly enhance Lufa Farms’ efficiency and sustainability. The integration of advanced AI-powered systems for predictive maintenance and automated environmental control could minimize resource waste and optimize yields. For instance, AI could predict potential equipment failures, allowing for timely repairs and preventing costly downtime. Exploring alternative energy sources, such as solar power, to reduce reliance on the electrical grid would significantly improve the environmental footprint.

Research into closed-loop systems for water and nutrient recycling could dramatically decrease water consumption and fertilizer usage. Imagine a system where nearly all the water used in the growing process is recycled and reused, drastically reducing the farm’s water footprint.

Future Expansion Strategies

Lufa Farms’ future expansion could involve strategic geographic expansion into new urban centers with high population density and a strong demand for locally sourced produce. This would require careful site selection, considering factors like access to infrastructure, transportation, and energy sources. Product diversification is another key strategy. Expanding beyond leafy greens to include a wider range of crops, such as fruits, herbs, and even certain root vegetables, would broaden the market reach and increase revenue streams.

Partnerships with local restaurants and grocery chains could create a robust distribution network, ensuring efficient delivery of fresh produce to consumers. Consider the possibility of Lufa Farms supplying specialty produce to high-end restaurants, establishing a premium brand image and commanding higher prices.

Potential Research Areas

Further research into optimizing plant varieties for vertical farming environments is crucial. Developing cultivars that thrive under specific lighting and nutrient conditions within the vertical farm setting could significantly boost yields and reduce resource requirements. Research into disease resistance and pest management strategies tailored to vertical farms is essential to minimize crop losses and reduce the reliance on pesticides.

A comprehensive life cycle assessment (LCA) of Lufa Farms’ vertical farming system would provide valuable data on its overall environmental impact, highlighting areas for further improvement. This data-driven approach would allow Lufa Farms to make informed decisions about resource allocation and sustainability initiatives. For example, a detailed LCA might reveal unexpected environmental hotspots within the system, prompting the development of more sustainable practices.

Visual Representation of Lufa Farms’ Technology

Imagine a sprawling, futuristic greenhouse, not some flimsy plastic affair, but a robust structure humming with technological efficiency. This isn’t your grandpappy’s tomato patch; this is Lufa Farms’ vertical farming marvel, a testament to controlled-environment agriculture taken to its zenith. Let’s delve into the visual spectacle.

Lufa Farms’ greenhouses are impressive structures, typically spanning several thousand square meters. They’re not your average glasshouses; think high-tech, climate-controlled behemoths built with durable, insulated panels designed to maximize light penetration while minimizing energy loss. The layout is meticulously planned, maximizing vertical space with tiered growing systems. Think a multi-story apartment building, but instead of humans, it’s brimming with leafy greens, vibrant peppers, and juicy strawberries.

Greenhouse Structure and Materials

The structure itself is a marvel of engineering, designed to withstand harsh weather conditions while maintaining a stable internal environment. High-performance insulation minimizes heat loss in winter and keeps things cool in summer, reducing reliance on energy-intensive heating and cooling systems. The outer panels are often made from durable, UV-resistant polycarbonate or similar materials, chosen for their light-transmitting properties and longevity.

Inside, the framework supports the multi-tiered growing systems, often using lightweight yet strong materials like aluminum. The entire structure is designed for optimal airflow and easy access for maintenance and harvesting.

Lighting Systems and Environmental Controls, Lufa Farms vertical farming technology and benefits

Lufa Farms’ success hinges on precise environmental control. Their lighting systems are far from basic fluorescent tubes. They utilize sophisticated LED lighting systems, carefully calibrated to provide the optimal spectrum and intensity of light for each crop at different growth stages. Think of it as a personalized sun for each plant, tailored to its needs. This is complemented by advanced climate control systems that regulate temperature, humidity, and CO2 levels, all monitored and adjusted in real-time using sophisticated sensors and automation.

It’s like having a highly skilled horticulturalist on duty 24/7, ensuring optimal growing conditions.

Automated Systems for Planting, Harvesting, and Transport

Forget back-breaking manual labor; Lufa Farms’ operations are largely automated. Sophisticated robotic systems handle planting, ensuring uniform spacing and depth for each seed or seedling. Automated watering systems deliver precise amounts of water and nutrients directly to the roots, minimizing waste and maximizing efficiency. As for harvesting, some facilities utilize robotic arms that gently pluck ripe produce from the plants, while others rely on a combination of automated and manual harvesting, depending on the crop type and stage of development.

Conveyor belts and automated transport systems move harvested crops to processing and packaging areas with impressive speed and precision. Imagine a perfectly choreographed ballet of robotic arms and conveyor belts, all working in perfect harmony.

Crop Growth Process from Seed to Harvest

The journey of a crop within Lufa Farms’ system is a carefully orchestrated process. Seeds are sown in specialized trays and placed in a controlled environment with optimal light, temperature, and humidity. As seedlings emerge, they’re monitored closely, with automated systems adjusting environmental parameters as needed. Once the plants reach a certain size, they’re transplanted to their designated growing locations on the vertical farming system.

Throughout the growing cycle, sensors monitor various parameters, and the system automatically adjusts environmental conditions to ensure optimal growth. The harvesting process is triggered by sensors that detect ripeness, ensuring that only mature produce is picked. From seed to harvest, the entire process is carefully managed to produce high-quality, consistent yields.

Closure

So, there you have it – Lufa Farms: a compelling case study in how vertical farming can redefine our relationship with food. By cleverly combining technology, sustainability, and community engagement, they’ve not only created a profitable business but also a model for a more resilient and eco-conscious food system. While challenges remain, the future of farming might just be looking up – literally.

From rooftop gardens to urban farms, the potential for this technology to transform our food landscape is truly awe-inspiring. Now, if you’ll excuse me, I’m off to cultivate my own miniature vertical farm – starting with a particularly ambitious basil plant.