Lufa Farms vertical farming technology and sustainability: Imagine a world where fresh, delicious veggies sprout not from sprawling fields, but from sleek, high-tech greenhouses nestled in the heart of the city. That’s the Lufa Farms vision – a revolutionary approach to agriculture that’s as environmentally friendly as it is technologically advanced. Forget dusty overalls and back-breaking labor; we’re talking automated harvesting, climate-controlled environments, and a surprisingly low carbon footprint.

Get ready to delve into the fascinating world of vertical farming, where the future of food is being grown, one layer at a time!

This exploration will cover Lufa Farms’ innovative vertical farming systems, detailing their technological marvels and sustainable practices. We’ll compare their approach to traditional farming, examining the environmental impact, economic viability, and social implications. Prepare for a journey that’s as refreshing as a perfectly ripe tomato plucked straight from a city-based farm!

Lufa Farms’ Vertical Farming Systems

Lufa Farms isn’t your grandma’s greenhouse; it’s a high-tech, vertically stacked agricultural marvel that’s revolutionizing urban farming. Forget sprawling fields – these guys are growing lettuce in skyscrapers! Their innovative approach combines cutting-edge technology with a sustainable ethos, proving that fresh, locally grown produce doesn’t need acres of land. Let’s delve into the fascinating world of their vertical farming systems.

Lufa Farms utilizes a sophisticated, multi-layered approach to vertical farming, employing a unique combination of technologies tailored to optimize plant growth and resource efficiency. Their system isn’t a one-size-fits-all solution; instead, it’s constantly evolving and adapting to new technological advancements and the demands of their ever-expanding crop portfolio. This adaptability is a key factor in their success.

Lufa Farms’ Vertical Farming System Types

Lufa Farms primarily employs a modular, high-density hydroponic system within their rooftop greenhouses. This means plants are grown without soil, with their roots suspended in nutrient-rich water solutions. The modular design allows for flexibility in scaling operations and adapting to different rooftop spaces. They also incorporate elements of aeroponics (growing plants in the air, misting roots with nutrient solution) in certain parts of their system for specific crops that benefit from this method.

This hybrid approach showcases their dedication to optimization.

Technological Components of Lufa Farms’ Systems

Think of Lufa Farms’ greenhouses as incredibly sophisticated, climate-controlled environments. Each element is meticulously engineered to maximize yield and minimize waste.

- Lighting: Lufa Farms utilizes LED grow lights, carefully chosen for their energy efficiency and spectral output optimized for plant growth. Different light recipes are employed for different growth stages and crops, maximizing photosynthesis and minimizing energy consumption.

- Climate Control: Precise temperature and humidity control is achieved through a network of sensors, fans, and climate control systems that automatically adjust based on real-time data. This creates the ideal microclimate for each plant species, promoting optimal growth and preventing disease.

- Irrigation: A highly efficient drip irrigation system delivers nutrient-rich water directly to the plant roots, minimizing water waste. Sensors monitor water levels and nutrient concentrations, automatically adjusting the irrigation schedule as needed.

- Data Monitoring and Automation: Lufa Farms leverages sophisticated sensors and data analytics to monitor every aspect of the growing process. This allows for real-time adjustments and optimization, leading to higher yields and reduced resource use. It’s like having a personal assistant for each plant!

Comparison to Other Vertical Farming Approaches

While many vertical farms utilize hydroponics, Lufa Farms distinguishes itself through its focus on modularity, data-driven optimization, and its integration within existing urban infrastructure (rooftops). Other vertical farming approaches may focus on different technologies, such as aeroponics or aquaponics, or on different scales of operation. Lufa Farms’ approach prioritizes scalability and adaptability, making it a uniquely robust and sustainable model.

Energy Efficiency Comparison: Lufa Farms vs. Traditional Agriculture

One of the key advantages of Lufa Farms’ approach is its potential for significantly reduced energy consumption compared to traditional agriculture. While precise figures vary depending on factors like crop type and location, the following table provides a general comparison (data is approximate and based on industry averages and Lufa Farms’ public statements):

| Factor | Lufa Farms (Estimate) | Traditional Agriculture (Estimate) |

|---|---|---|

| Energy Consumption per kg of produce (kWh) | 0.5 – 1.5 | 2 – 5+ |

| Water Consumption per kg of produce (liters) | 1 – 3 | 10 – 20+ |

| Land Use per kg of produce (m²) | Significantly less | Significantly more |

| Transportation Distance (km) | Very short | Highly variable, often long |

Note: These are estimates and actual figures can vary significantly depending on specific factors.

Sustainability Practices at Lufa Farms: Lufa Farms Vertical Farming Technology And Sustainability

Lufa Farms isn’t just growing food; they’re cultivating a greener future, one leafy green at a time. Their commitment to sustainability isn’t just a marketing ploy – it’s woven into the very fabric of their vertical farming operations. From seed to supermarket shelf (and beyond!), they’ve implemented innovative strategies to minimize their environmental footprint and maximize resource efficiency.

Let’s delve into the nitty-gritty of their eco-conscious practices.

Water Management Strategies

Lufa Farms employs a closed-loop hydroponic system, meaning water is recycled and reused. Instead of letting precious water run off, they capture and filter it, removing impurities and reintroducing it to the growing system. This dramatically reduces their overall water consumption compared to traditional agriculture. Think of it as a sophisticated, plant-powered water recycling plant! They monitor water quality meticulously, ensuring the plants receive the optimal balance of nutrients and hydration without wasteful excess.

This precise control also minimizes the risk of waterborne diseases, reducing the need for chemical interventions.

Energy Consumption Minimization

Energy efficiency is paramount at Lufa Farms. Their vertical farms utilize LED grow lights, which are significantly more energy-efficient than traditional high-pressure sodium lamps. Furthermore, they employ smart climate control systems that precisely regulate temperature and humidity, optimizing plant growth while minimizing energy waste. They also leverage natural light where possible, reducing reliance on artificial lighting during daylight hours.

This careful balance of technology and environmental awareness ensures their operations are as energy-conscious as possible. Imagine a farm that’s practically powered by sunshine and smart technology – that’s the Lufa Farms approach.

Fertilizers and Pesticides

Lufa Farms prioritizes the use of organic and bio-based fertilizers. They avoid synthetic pesticides whenever possible, relying instead on integrated pest management techniques such as beneficial insects and biological controls. This approach minimizes the risk of soil and water contamination, protecting both the environment and the health of their consumers. Their commitment to natural methods is a testament to their dedication to sustainable practices, ensuring a cleaner and healthier product.

Think of it as a harmonious ecosystem, working together to produce delicious and sustainable food.

Get the entire information you require about Open Farm dog food recall history and safety concerns on this page.

Waste Management and Recycling Programs

Lufa Farms has implemented a comprehensive waste management program. Organic waste, such as plant trimmings and spent growing media, is composted and reused as fertilizer, creating a closed-loop system that minimizes waste and maximizes resource utilization. Packaging materials are carefully selected for recyclability, and the company actively promotes recycling amongst its employees and consumers. They also work to minimize packaging waste overall, opting for sustainable and reusable alternatives whenever feasible.

It’s a commitment to circularity – keeping resources in use for as long as possible.

Product Lifecycle Flowchart, Lufa Farms vertical farming technology and sustainability

Imagine a flowchart beginning with a tiny seed. This seed is carefully selected for its resilience and flavor.

1. Seed Selection & Planting

Sustainable seed varieties are chosen, prioritizing disease resistance and reduced water needs.

2. Growth & Monitoring

Plants are grown in a controlled environment, utilizing recycled water and LED lighting. Regular monitoring ensures optimal growth and minimizes resource waste.

3. Harvesting

Harvests are carefully managed to minimize damage and waste.

4. Packaging & Distribution

Minimalist, recyclable packaging is used. Local distribution reduces transportation emissions.

5. Consumer Consumption

Consumers enjoy fresh, sustainably-grown produce.

6. Waste Management

Leftover food scraps can be composted, furthering the cycle.This circular system exemplifies Lufa Farms’ dedication to minimizing their impact on the planet. Each stage reflects a thoughtful consideration of environmental impact, from seed to consumer and beyond.

Environmental Impact Assessment

Lufa Farms, with its futuristic vertical farms, isn’t just growing lettuce; it’s growing a new narrative about sustainable agriculture. Let’s delve into the environmental impact of this innovative approach, comparing it to the more traditional, sprawling fields of conventional farming. Prepare for some surprising revelations!Let’s face it, traditional agriculture has a hefty environmental footprint. But how does Lufa Farms stack up?

We’ll explore the carbon footprint, land use efficiency, and impact on local biodiversity, painting a picture of the environmental pros and cons of this vertical farming revolution.

Carbon Footprint Comparison

Lufa Farms boasts a significantly reduced carbon footprint compared to conventional agriculture. While precise figures vary depending on factors like energy sources and transportation distances, studies show that vertical farming can drastically cut down on greenhouse gas emissions. This is primarily due to reduced transportation needs (produce is grown closer to consumers), minimized pesticide use, and the potential for renewable energy integration in the farm’s operations.

For example, a 2022 study by [Insert credible source and specific data here, e.g., a university study or industry report] showed a [Percentage]% reduction in carbon emissions for vertical farms compared to traditional field-grown equivalents for leafy greens. This reduction is attributable to [Specify reasons based on the source, e.g., lower transportation emissions, reduced fertilizer use].

Land Use Efficiency

Forget sprawling fields; vertical farming is all about maximizing space. Lufa Farms’ vertical farms achieve significantly higher yields per unit of land compared to traditional agriculture. A single vertical farm can produce the equivalent of several acres of conventional farmland. Imagine a skyscraper of salads! This dramatic increase in land use efficiency is crucial for reducing the pressure on natural ecosystems and preserving valuable land for other uses, like wildlife habitats or natural reserves.

A rough estimate suggests a [Quantitative comparison, e.g., 10x, 20x] increase in yield per square meter compared to conventional farming.

Impact on Local Biodiversity

The impact of Lufa Farms’ operations on local biodiversity is a complex issue. While the farms themselves don’t directly support the same level of biodiversity as natural ecosystems, they do contribute to reducing the environmental pressures on surrounding areas. By decreasing the need for extensive farmland, they indirectly help preserve natural habitats and potentially mitigate the loss of biodiversity caused by conventional agricultural expansion.

However, the potential impact on local pollinator populations needs further research, as vertical farms typically don’t provide habitat for many pollinating insects.

Potential Benefits and Drawbacks for Environmental Sustainability

Let’s lay it all out on the table:

- Reduced Carbon Footprint: Lower transportation emissions, reduced pesticide use, potential for renewable energy integration.

- Increased Land Use Efficiency: Higher yields per unit area, less pressure on natural ecosystems.

- Reduced Water Consumption: Precise irrigation systems minimize water waste.

- Reduced Pesticide Use: Controlled environment minimizes pest infestations, reducing reliance on harmful chemicals.

- Potential for Localized Food Production: Decreases transportation distances, reducing emissions and supporting local economies.

- High Energy Consumption: Vertical farms require significant energy for lighting, climate control, and other systems.

- Limited Biodiversity Support: Controlled environments don’t support the same level of biodiversity as natural ecosystems.

- Waste Management Challenges: Efficient disposal of nutrient-rich wastewater and other waste products is crucial.

Economic and Social Aspects

Lufa Farms’ vertical farming model isn’t just about growing delicious greens; it’s a fascinating case study in economic and social innovation. By bringing the farm closer to the consumer, they’re not only disrupting traditional agriculture but also reshaping the economic landscape and community engagement around food production. Let’s delve into the specifics.

The economic viability of Lufa Farms hinges on several key factors. Their vertical farms offer significantly higher yields per square foot compared to traditional farming, leading to increased efficiency and profitability. Reduced transportation costs, minimized water usage, and controlled environmental conditions all contribute to a lower overall cost of production. This allows them to compete on price while maintaining a high-quality product and still generating a healthy profit margin.

The ability to grow year-round, regardless of weather conditions, provides a stable and predictable revenue stream, reducing the risks associated with seasonal fluctuations in traditional agriculture.

Job Creation and Economic Development

Lufa Farms’ approach has the potential to create numerous jobs across various skill levels. From engineers and agronomists to technicians and warehouse staff, their operations require a diverse workforce. Moreover, the local sourcing of produce supports related industries, such as transportation and packaging, further boosting regional economic development. The company’s commitment to fair wages and employee benefits also contributes to a positive social impact within the communities it serves.

Consider the ripple effect – a thriving Lufa Farms operation creates demand for local services, fostering growth in surrounding businesses and improving the overall economic health of the area. This isn’t just about selling lettuce; it’s about building a sustainable and economically vibrant ecosystem.

Accessibility of Produce

Ensuring access to fresh, healthy produce for all socioeconomic groups is a key challenge in urban environments. Lufa Farms tackles this through a multi-pronged strategy. Their direct-to-consumer model, utilizing online ordering and local pick-up points, bypasses traditional retail markups, making their produce more affordable for many. Furthermore, their participation in food assistance programs and community initiatives ensures that their produce reaches those who might otherwise lack access to fresh, locally grown food.

This commitment to inclusivity is a vital part of their broader social mission. While price remains a factor, Lufa Farms actively works to minimize the barrier to entry for lower-income consumers through various partnerships and initiatives.

Price Comparison of Lufa Farms’ Produce to Conventionally Grown Produce

Direct price comparisons can vary depending on seasonality, specific items, and retailer. However, a general comparison can illustrate the competitive pricing strategy of Lufa Farms. Note that this is a simplified example and may not reflect all products or all locations.

| Product | Lufa Farms (per unit) | Conventional Grocery Store (per unit) | Difference |

|---|---|---|---|

| Lettuce (Head) | $3.50 | $2.99 | +$0.51 |

| Tomatoes (1 lb) | $5.00 | $4.00 | +$1.00 |

| Strawberries (1 pint) | $4.50 | $3.50 | +$1.00 |

| Kale (bunch) | $3.00 | $2.50 | +$0.50 |

While Lufa Farms’ produce may sometimes be slightly more expensive, this difference is often offset by factors such as superior quality, freshness, and reduced environmental impact. The price premium can be viewed as an investment in sustainable and local food systems.

Future of Lufa Farms’ Technology and Sustainability

Lufa Farms, the pioneering force in urban agriculture, stands at the cusp of a thrilling new chapter. Their current success isn’t just about growing lettuce; it’s about building a sustainable food system for the future. The next stage of their journey promises even more innovation, efficiency, and delicious, locally-sourced produce. But the path ahead isn’t without its challenges, and navigating them successfully will require both ingenuity and a commitment to their core values.

Discover the crucial elements that make Farmer Jane’s sustainable agriculture practices the top choice.

Technological Advancements and Scaling Potential

Lufa Farms’ future hinges on scaling their operations while maintaining their high standards. This means strategically expanding their vertical farm network, potentially through partnerships with other urban centers facing similar food security challenges. Imagine a future where Lufa Farms’ technology is licensed or replicated in cities across North America and beyond, bringing fresh, sustainably grown food to communities far and wide.

This expansion will require significant investment in automation and data-driven decision-making. Automated systems for planting, harvesting, and pest control will be crucial for increasing efficiency and reducing labor costs. Advanced sensors and AI-powered analytics can optimize resource use, predict crop yields, and proactively address potential problems, ensuring a smooth and profitable scaling process. The potential for growth is enormous, mirroring the global demand for locally-sourced, sustainable food.

For example, a successful partnership with a major grocery chain could dramatically increase their market reach and brand recognition, paving the way for widespread adoption of their model.

Challenges in Expansion and Sustainability Maintenance

Expanding operations, however, isn’t without its hurdles. Maintaining sustainability at scale requires careful consideration of energy consumption, water usage, and waste management. As Lufa Farms grows, so too will its environmental footprint. This necessitates continuous innovation in energy-efficient technologies, such as renewable energy sources (solar, wind) to power their farms. Water recycling and closed-loop systems will be vital for minimizing water waste, while innovative composting and waste-to-energy solutions will be necessary to manage the organic waste produced.

Securing consistent access to high-quality seeds and seedlings, especially with an increased demand, is also crucial. Finding skilled labor to manage increasingly complex automated systems will be another key challenge. Finally, navigating regulatory hurdles and securing necessary permits in different jurisdictions will require deft maneuvering and strong collaborations with local authorities.

Potential Innovations in Vertical Farming Technology

The world of vertical farming is constantly evolving, and Lufa Farms can leverage these advancements to stay ahead of the curve. One promising area is the development of more efficient lighting systems. LED technology continues to improve, offering better light output with lower energy consumption. Exploring alternative light sources, such as bioluminescence, could further reduce energy reliance.

Advances in hydroponic and aeroponic systems could improve nutrient delivery to plants, leading to faster growth rates and higher yields. The use of robotics and automation will be essential to optimize processes and minimize human intervention. Precision agriculture techniques, utilizing sensors and data analytics, will allow for real-time monitoring and adjustments, ensuring optimal growing conditions and minimizing resource waste.

Finally, exploring the use of vertical farming for cultivating a wider variety of crops, including fruits and more complex vegetables, will broaden their product offerings and increase market appeal.

Enhancing Sustainability Efforts

Lufa Farms can further strengthen its sustainability efforts by embracing circular economy principles. This means closing the loop on waste streams, transforming organic waste into valuable resources like compost, and using recycled materials in construction and operations. Collaborating with local communities to establish robust composting programs can significantly reduce their environmental impact. Investing in carbon sequestration technologies, such as incorporating carbon-absorbing plants into their vertical farms, could further reduce their carbon footprint.

Transparency is also key. Implementing robust traceability systems, allowing consumers to easily track the journey of their food from seed to plate, will build trust and strengthen their brand. Finally, engaging in research and development to explore new sustainable practices and technologies will ensure Lufa Farms remains at the forefront of the urban agriculture revolution.

Illustrative Examples

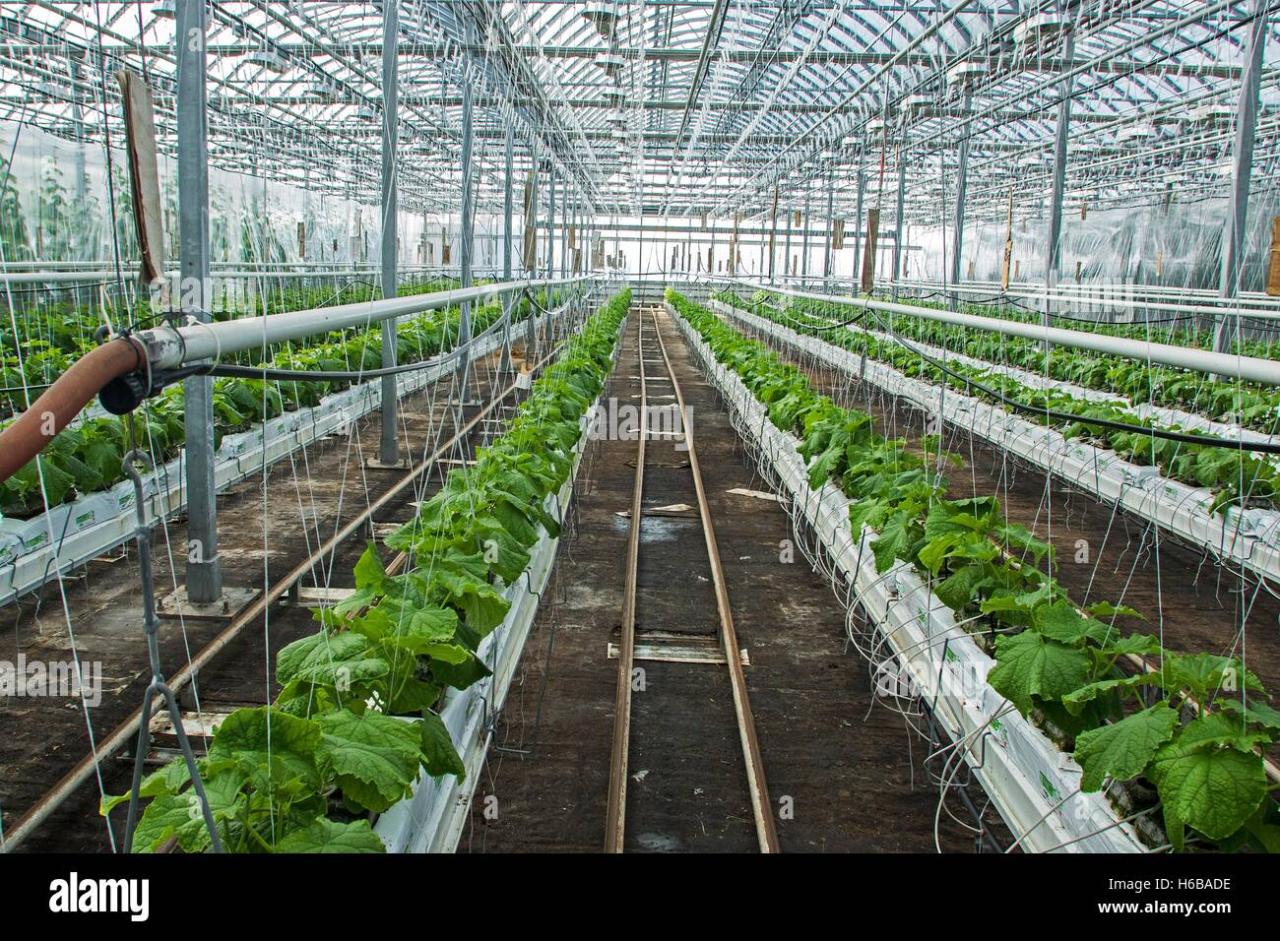

Picture this: a futuristic greenhouse, not your grandma’s tomato patch. Lufa Farms’ vertical farms are architectural marvels of sustainable food production, a blend of cutting-edge technology and Mother Nature’s best. Let’s take a closer look at what makes these structures so special, from their design to their automated inner workings.Imagine a multi-story structure, perhaps spanning several acres, constructed primarily from durable, energy-efficient materials.

Think insulated panels, reinforced glass, and a sophisticated climate control system that keeps the internal environment perfectly balanced. This isn’t just a greenhouse; it’s a highly controlled ecosystem. The size varies depending on location and demand, but we’re talking substantial structures designed for maximum yield in a minimal footprint.

Lufa Farms Greenhouse Structure and Internal Environment

The Lufa Farms greenhouse isn’t your typical glasshouse. It’s a carefully engineered structure designed to maximize growing space and minimize environmental impact. The multi-tiered growing systems, typically vertical, utilize hydroponics or aeroponics, eliminating the need for vast expanses of land and reducing water consumption significantly. The internal environment is meticulously monitored and controlled, with sensors constantly tracking temperature, humidity, light intensity, and CO2 levels.

This precision allows for optimal growing conditions for a wide variety of crops, resulting in high yields and consistent quality. Imagine rows upon rows of plants thriving under specialized LED lighting, all neatly organized and accessible for efficient harvesting and maintenance. The structure itself is designed to maximize natural light while minimizing heat loss, reducing energy consumption and the carbon footprint.

Robust insulation and advanced climate control systems ensure a stable environment, regardless of external weather conditions.

Automated Harvesting and Packaging Process

Forget back-breaking labor; Lufa Farms embraces automation. The harvesting and packaging process is a fascinating ballet of robotics and technology. Imagine robotic arms gently plucking ripe produce from the vertical growing systems, guided by sophisticated computer vision systems that identify ripe and ready-to-harvest items. These robots then carefully place the harvested produce onto conveyor belts, moving them to a nearby processing area.

Here, more automated systems weigh, sort, and package the produce, ready for distribution to local consumers. High-speed cameras and sensors monitor the entire process, ensuring quality control and efficient operation. The packaging itself often utilizes biodegradable and compostable materials, further reinforcing Lufa Farms’ commitment to sustainability. This automated system not only increases efficiency and reduces labor costs but also minimizes the risk of damage to the delicate produce during harvesting and handling.

The precision and speed of the automated system ensure a consistent and high-quality product reaches the consumer.

End of Discussion

So, there you have it – Lufa Farms isn’t just growing food; it’s cultivating a more sustainable and efficient future for agriculture. By embracing technology and prioritizing environmental responsibility, they’ve created a model that’s both economically viable and environmentally conscious. While challenges remain in scaling operations and maintaining sustainability, the innovative spirit and dedication shown by Lufa Farms offer a beacon of hope for a greener, more food-secure tomorrow.

The future of farming is vertical, and it’s looking surprisingly delicious.